DRILLING & WORKOVER

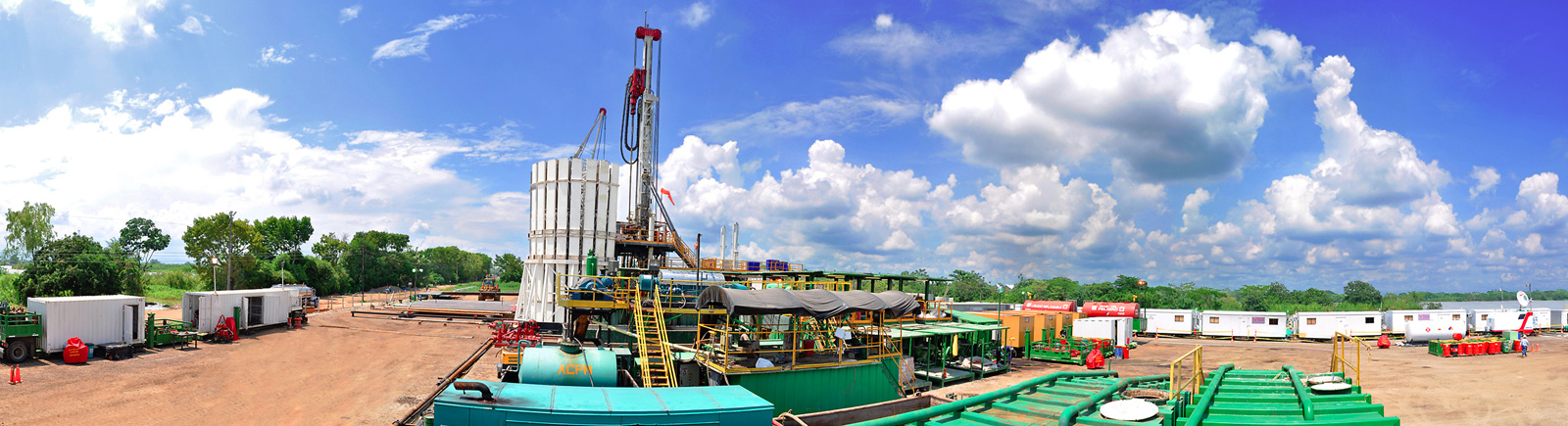

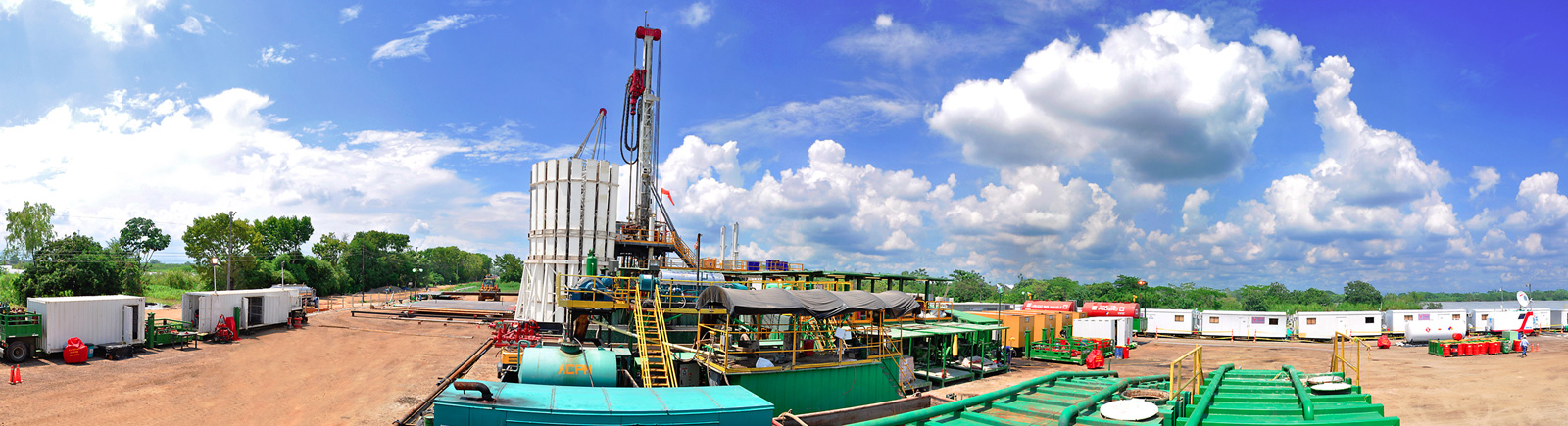

KWDC has equipped its fleet with innovative automatic hydraulic drilling rigs that have proven their capabilities under a wide range of climatic conditions.

Our customers can choose from a range of drilling rigs, including HH300, HH220, HH102. These modern drilling rigs perform at the highest technological level while fully meeting all safety and environmental requirements.

The rigs are constructed and manufactured in compliance with the API standard and the most recent legislation. All rigs are fully automatic and joystick-controlled.

KWDC has a long-standing tradition in offering a range of workover operations. Over the past 5 years, the company performed more than 250 workovers and well completions for different companies.

KWDC performs standard workovers of production wells, such as replacement of down-hole pumps, rinsing of sand plugs across perforations, removal of scale or wax deposits, special completions (installation of rotary down-hole pumps, down-hole pressure gauges and bridge plugs), repairs of disposal wells and cementation operations, but also general workovers, like isolation of produced horizons, development of new and high-pressure horizons, well stimulation via acid treatment and hydraulic fracturing, special completions (packer assemblies, subsurface safety valves, etc.), well performance testing. Finally, it performs completion of underground injection-withdrawal wells, including casing, milling, under-reaming, gravel packing and final completion of the well with gas-tight tubing and packer assembly outfitted with a subsurface safety valve.

MAINTENANCE

Maintenance activities on main and auxiliary equipment of KWDC Drilling and Workover rigs are developed with attention to reducing hazardous conditions for personnel and during downtime. KWDC performs and updates a rigorous preventive and corrective maintenance plan where routines are defined according to the manufacturer's recommendations, the experience of our staff and the operational context of each machine.

Preventive measures are scheduled from the general maintenance program by software assistance. Maintenance staff performs the tasks indicated in the routine. The routine form is registered into the KWDC database.

The record of corrective maintenance, operating parameters, and faults of each element is a fundamental part of the performance statistics and cause analysis of incidents.

SERVICES

KWDC is an emerging drilling contractor that develops and optimizes drilling services utilizing the new generations' hydraulic drilling rigs HH type, manufactured by Drillmec.

We are able to provide a fully integrated service of rig management, rig customization, rig engineering and design, technical assistance, maintenance with in house spare parts supply.

In addition to the usual drilling services, we are able to adapt the best suitable design and technical specifications of the drilling rigs to fit the purpose as per local working conditions and the environment.

We provide innovative drilling services for oil, gas and water wells.